|

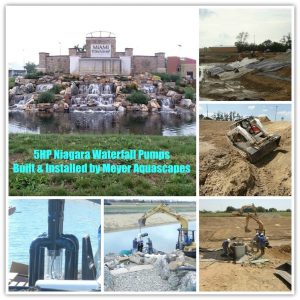

| 3HP Niagara 2 Sled Mount Waterfall |

Waterfall projects present various challenges that are not encountered with display units. When selecting a fountain, the pattern dimensions, based on horsepower are automatically supplied. There are no unknowns. The patterns have been tested and measured. This is not the case with waterfalls or streams. Each project is unique. Each project requires a specific amount of water pumped a specified height through a specific piping system. Usually, the piping system can be determined at design time. Periodically, however, the pipe run is buried and is unknown. This presents the greatest challenge in selecting a waterfall pump.

-

The power available. Some pumps are only available in specific voltages. Periodically, there is only a limited amount of power available (amperage).

-

The amount of water needed. This is normally expressed as the width of the waterfall (weir) and the thickness of the flow over the waterfall. This may also be expressed as gallons-per-minute, gallons-per-hour or cubic-meters-per hour. With streams, additional pieces of information are necessary for this calculation: A) Stream length, B) The composition of the stream bottom. A steep stream requires more water. Streams with rocks or weeds require less water than clean streams.

-

The elevation that the water must be pumped. This is measured from the source ponds surface to the highest point that the water is pumped or the destination ponds surface, whichever is higher. This is referred to as “static head”

-

The piping system. This includes the pipe diameter, the length of pipe and the number and types of fittings. This can be difficult to determine if the piping has been buried. In this case a “best guess” is provided. When guessing, it is prudent to select a solution closer to the center of a pump curve (see pump curve explanation below). The piping system and the volume of water required determine the amount of “dynamic head”, pressure requirements due to piping losses.

- If the volume was provided based on weir width and flow thickness, I use a Bazin table to determine the amount of water needed. This is not a linear calculation. Tripling the flow thickness, quadruples the volume needed.

- Once the target volume is determined, I calculate the amount of dynamic head generated by the piping system. This value added to the elevation creates “total dynamic head”.

- I compare the volume and head required with various pump curves. Pump curves are either provided by the pump manufacturer or by Aqua Control. These curves show the relationship between the volume pumped and the height achieved (head). This is an iterative process. If there is not an exact hit, and there never is, I adjust the target volume and recalculate total dynamic head. I continue adjusting the volume requirements until I find one or more pumps that approximate the initial target volume at the required head.

- When the selection process reveals various pumps, I select one or more of these solutions for quoting the distributor. I prefer selecting a pump nearer the center of the pump curve. This is usually a more efficient area for running the pump. Additionally, if there was buried pipe, I will select a pump that runs nearer the center of the curve to allow for the greatest variance of dynamic head.

There are other issues that must be addressed prior to quoting:

- The type of mount (horizontal, vertical or sled) required. Will the unit be installed in a wetwell or will it be installed directly in the pond? Aqua Control offers a patented sled mount design that allows the pump to be installed directly in the pond.

- The use of a flexible hose. Flexible hose may be attached to the pump outlet. This is mandatory if the unit is a sled mount. This also may be used in wetwells to adjust for inexact alignment between pump and hard piping.

- The size of the check valve. Check valves are required to prohibit the backflow of water through the pump when the pump it turned off. This keeps the pump from running in reverse, possibly damaging the bearings, and it stops the upper pond from draining into the lower pond.

|

| 3HP & 5HP Angel Waterfall Pumps create this beautiful feature on KoOlina Golf Course in Hawaii. |

Although this pump selection process appears somewhat cumbersome, the use of a spreadsheet simplifies this. Usually, a pump can be selected within moments. Although we publish pump curves, it is always prudent to contact Aqua Control for assistance is sizing these units.

Pricing and sizing assistance can be obtained thru your local Aqua Control Distributor. Use our ‘Find A Distributor’ tool to locate Aqua Control Distributors in your area!